Fluid Residuum

Fluid Residuum is a site-specific material investigation into the overlooked and so-called “waste” materials produced in large volumes by the construction industry. In collaboration with the local gravel company BEER SA in Rabius-Switzerland, we have been exploring alternative uses for gravel quarry silt which is usually used as landfilling material.

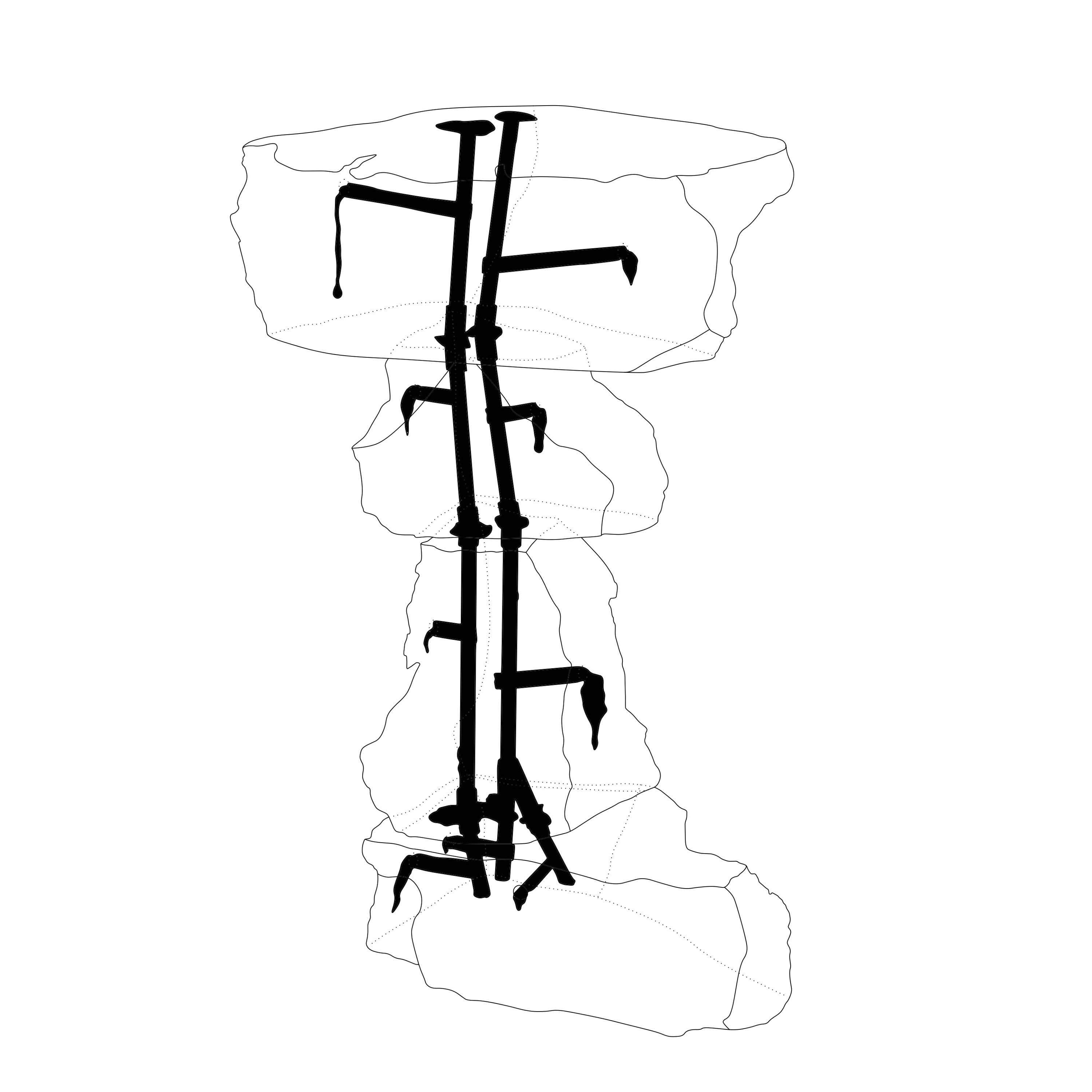

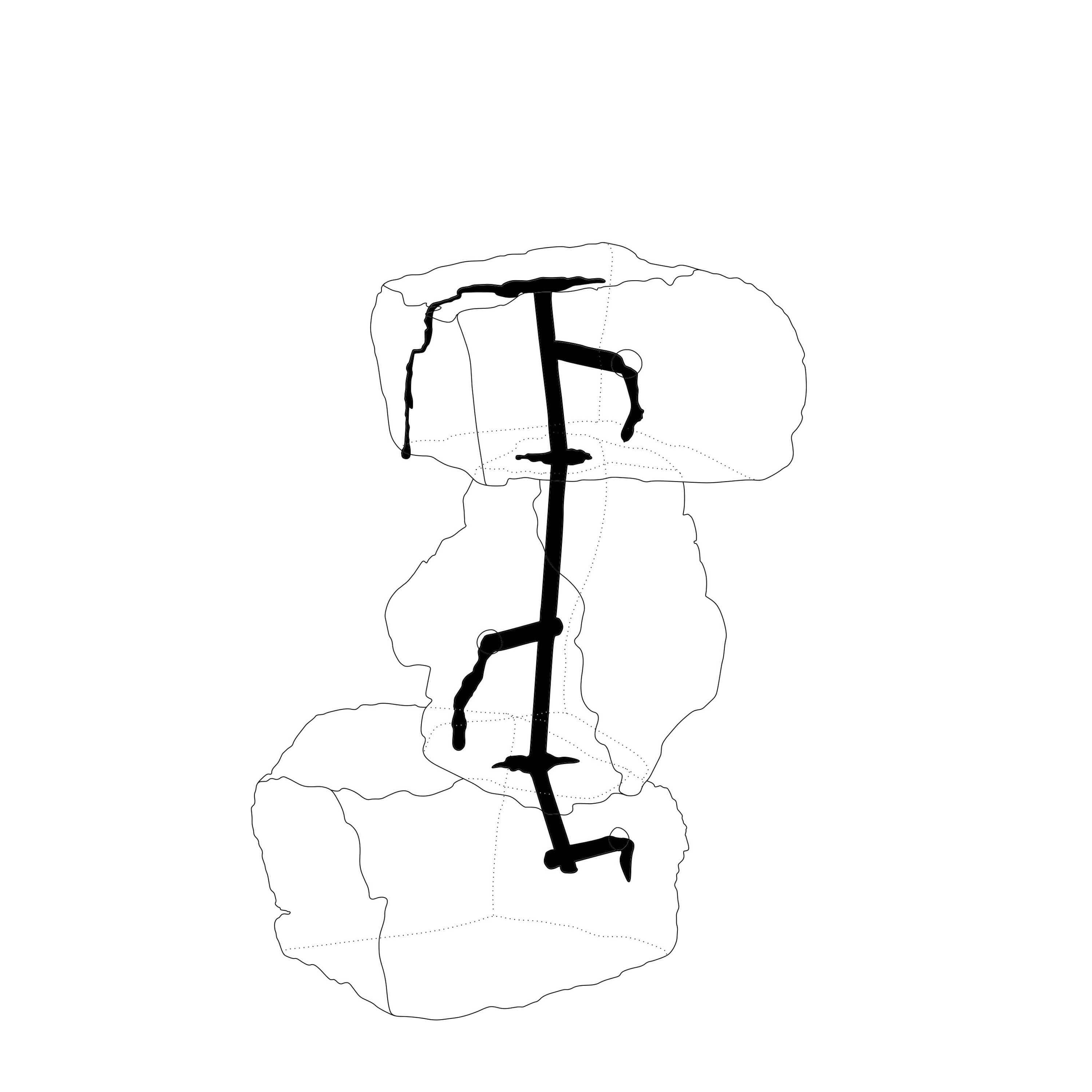

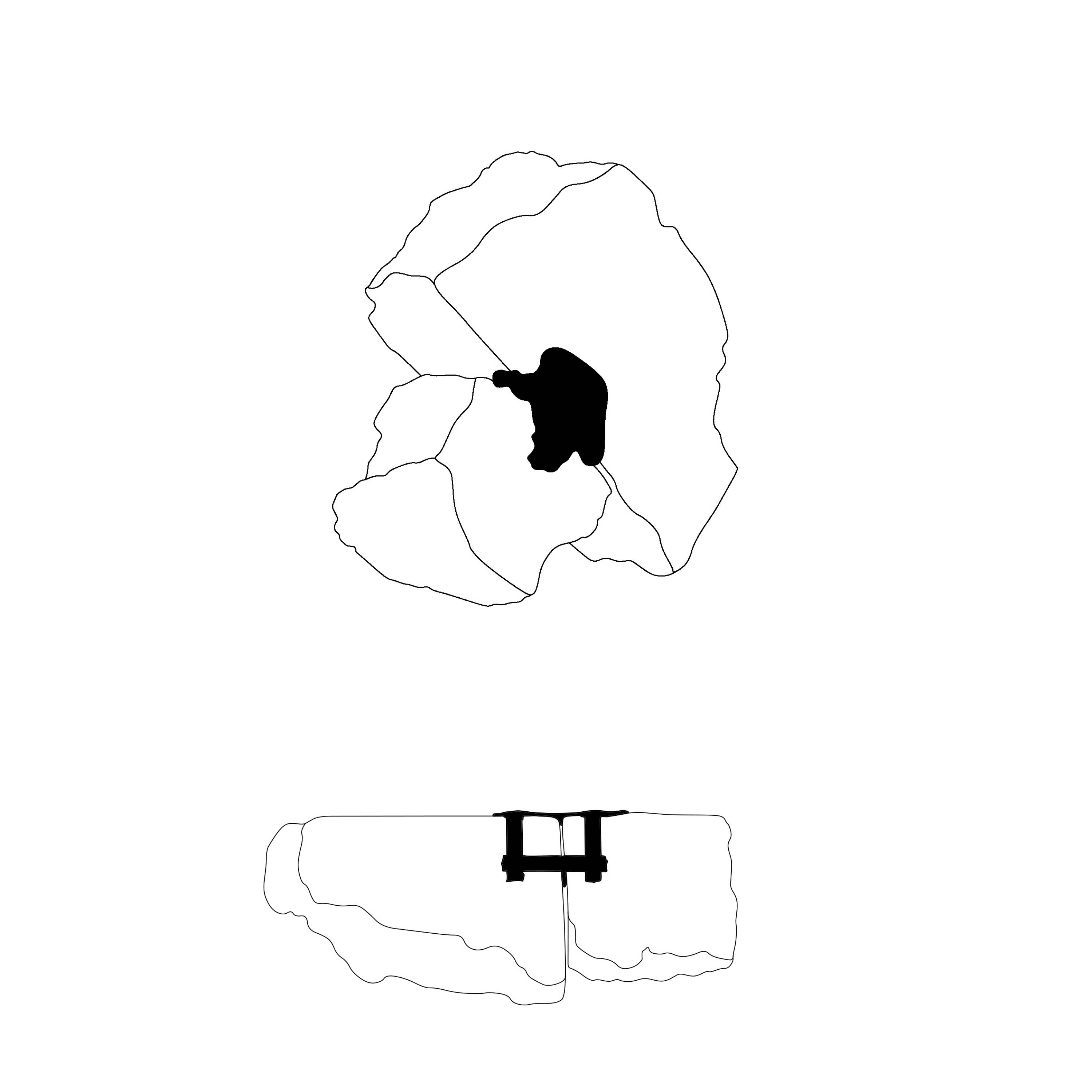

Rain-shaped surfaces were captured from the site and sculpted into blocks. Celebrating the rough and naturally eroded look of the material, “as found” pieces were minimally intervened. Kiln fired brick-like fragments of silt were joined with recycled tin to create a series of pedestals.

Rain-shaped surfaces were captured from the site and sculpted into blocks. Celebrating the rough and naturally eroded look of the material, “as found” pieces were minimally intervened. Kiln fired brick-like fragments of silt were joined with recycled tin to create a series of pedestals.

Fluid Residuum 01, 02, 03. SE, 2022.

Fluid Residuum 01, 02, 03. SE, 2022.Quarry silt is a by-product of the gravel industry. It is generated during sand and gravel processing; and essentially corresponds to the fine fractions which can not be used in concrete mi xtures. It is a non-commercial, unavoidable and non-hazardous “waste” material.

Globally, the ratio of quarry silt from the total extracted material can vary between 5-40% depending on the site geology. Construction industry makes up the 75% of the total sand and gravel demand, which is yearly 37,5 billion tons. Considering 87% of sand and gravel demand is met by mining, avg. 15% of the extracted material corresponds to 4.9 billion tons of by-product.

It is a very fine-grained and homogeneous mineral mixture (grain size smaller than 0.063 millimeter). They consist of finely divided silicates (quartz, feldspar), carbonates (calcite, dolomite) and clay minerals (illite, chlorite, montmorillonite/smectite, kaolinite).

Silt is collected in water and then pumped into lagoons to settle out. Ideally the water is recycled out of the sludge via filter presses. Using filter presses speeds up the process and eliminates the need for settling lagoons. The main use of quarry silt is as landfill material for filling the gap of the quarried space and for road constructions. When used as landfiller, it needs to be mixed with other materials which have bigger grain sizes. Otherwise, it might cause colmation if it reaches river beds and reduce ground permeability.

Investigating into reusing this by-product contributes to more efficient use of resources and revaluation of the overlooked materials, as well as reduces grey energy.

Quarry silt pond. SE, 2022.

Quarry silt pond. SE, 2022.Gravel silt which is left to settle out in the lagoon is exposed to weathering** and erosion* in small scale. Especially for a material which has a clay-like consistency, it is possible to observe how natural forces like rain, wind and temperature changes could shape it.

Pattern of rain drops on a surface which has smoothened by water flow. SE, 2022.

Pattern of the direction of water flow on a smooth surface which was shaped by flowing water. SE, 2022.

Wire cutting on site. SE, 2022.

Fragments taken from the quarry silt pond. SE, 2022.

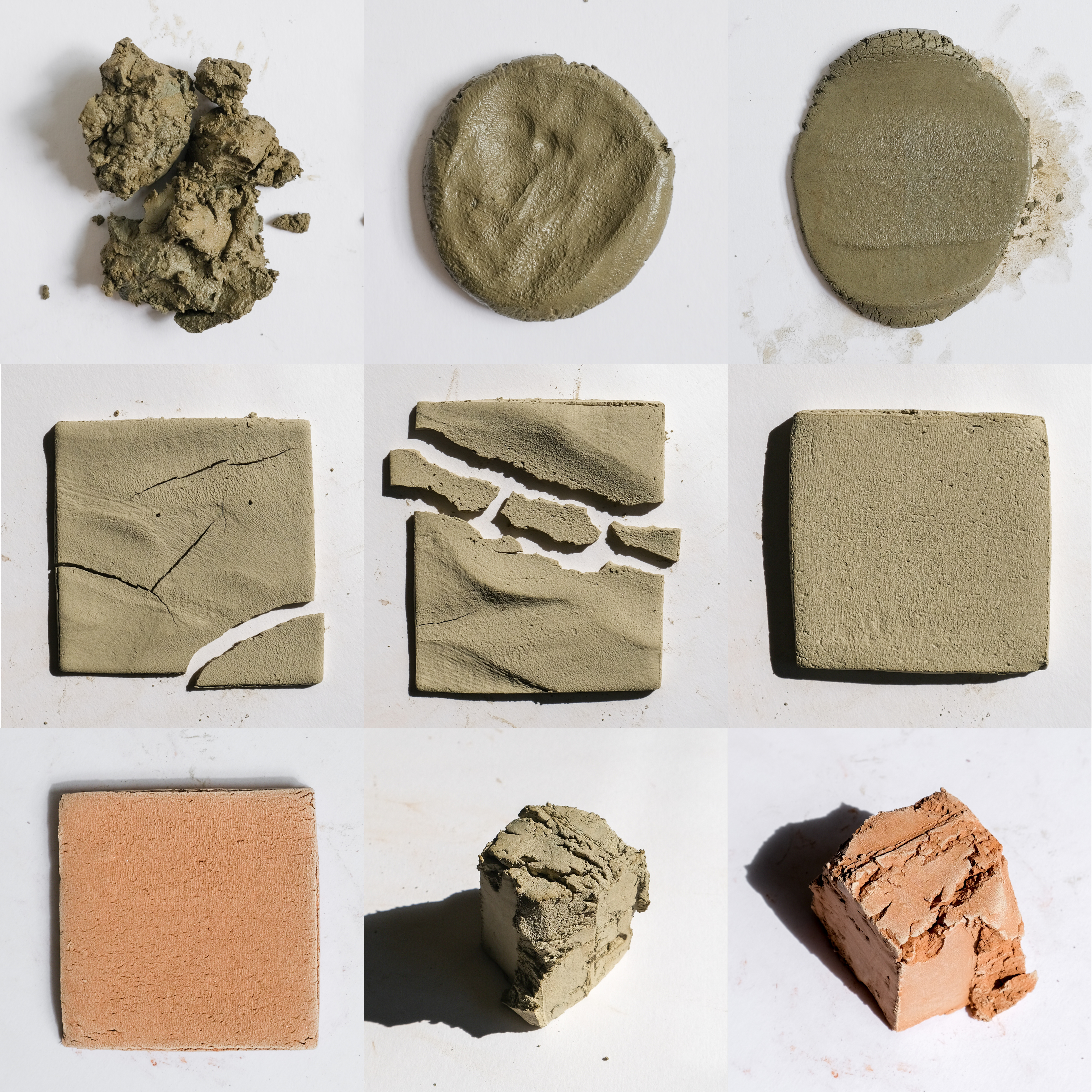

Fragments taken from the quarry silt pond. SE, 2022.Basic tests have been carried out to understand the elasticity, formability limits and physical structure of the material. Although it has a clay-like consistency, plastic behavior and permeability are lower in the silt mixture than usual pottery clay mixtures. As a result, the material cracks more than usual clay while shaping and drying. However, it performs as a firm material when kiln fired, which makes it structurally functional.

Apart from the decorative purposes, glazing is the most common method to protect the ceramic surfaces against water, dirt, as well as wear and tear. During firing, glaze ingredients melt and join with the sintered clay body to form a coating layer.

Knowing the strong joining ability of glazes with the fired earth body, the question has arised if an ordinary ceramic glaze could be used as a joint, to create a structural element with the silt blocks.

Although the technique of using glaze to join two blocks worked well, it was not deemed to be the ideal joint for higher sizes and cantilever parts. The object size is limited with the kiln size, it requires support around the blocks and it is a permanent joint that can not be seperated.

Since the unstable silt blocks became stone blocks after kiln-firing, stone joining techniques were also studied. Usual joints like screws, mortar and glue are the known options; however we wanted to look into a more flexible technique that the cracks and gaps of the fragments can be used as a benefit.

Inspired by the metal clamps of the ancient stone architecture, we recycled old tin products and poured the molten tin in the pre-drilled channels within the fragments.

Through the history and around the world, metal clamps were used in the stone temple architecture. They were used for binding the cut-stone blocks, as a reinforcement element in masonry. The earliest examples are from the Egyptian temples from 2500 BC and the other examples can be seen in Greek and Roman temples. They were in the shapes of H, T, dovetail, butterfly and double T. Iron was the most common material for the metal clamps, followed by lead and bronze.

Double channeled tin clamp. SE, 2022.

Double channeled tin clamp. SE, 2022. Single channeled tin clamp. SE, 2022.

Single channeled tin clamp. SE, 2022. Tin clamp. SE, 2022.

Tin clamp. SE, 2022. Studio view. SE, 2022.

Studio view. SE, 2022.

Fluid Residuum 01. SE, 2022.

Fluid Residuum 02. SE, 2022.

Fluid Residuum 03. SE, 2022.

Project info

2022 - Rabius Graubünden - CH

Quarry silt and recycled tin

In collaboration with BEER SA

References

(*)Erosion is the removal and transport of surface materials (soil, rocks, mud, sediments, etc.) through the actions of wind, water, ice, and gravity. Erosion involves the movement of rocks and minerals by agents of water, ice, snow, wind, waves, and gravity and transported and deposited in other location.

(**)Physical weathering, also called mechanical weathering, is a process that causes the disintegration of rocks, mineral, and soils without chemical change. It can occur due to temperature, pressure, frost, root action, and burrowing animals.

Csetenyi L. et al. (2015) Feasibility of utilising quarry fines and waste silts to manufacture synthetic lightweight sand. Magazine of Concrete Research, vl 67.

Green J.A. et al. (2005). Hydraulic impacts of quarries and gravel pits.

Kündig, R., et al. (1997): Die mineralischen Rohstoffe der Schweiz, Schweizerische Geotechnische Kommission.

Macheyeki, A., et al. (2020): Applied Geochemistry. Advances in Mineral Exploration Techniques. Elements of exploration geochemistry.

Maskova L. et al. (2019). Assessment of silt from sand and gravel processing as a suitable sub-soil material in land restoration: a glasshouse study. Chemosphere.

Mitchell C. (2009). Quarry fines and waste. Quarries and Mines. British Geological Survey.

Morley D.J. et al. (2022). A database for the stocks and flows of sand and gravel. MDPI

UNEP. (2022). Sand and sustainability: 10 strategic recommendations to avert crises.